In response to the different needs of manufacturers, HICOCA Taiwan has developed products for different markets to create a one-stop production line, allowing owners to save time, allowing a higher yield and lower production waste.

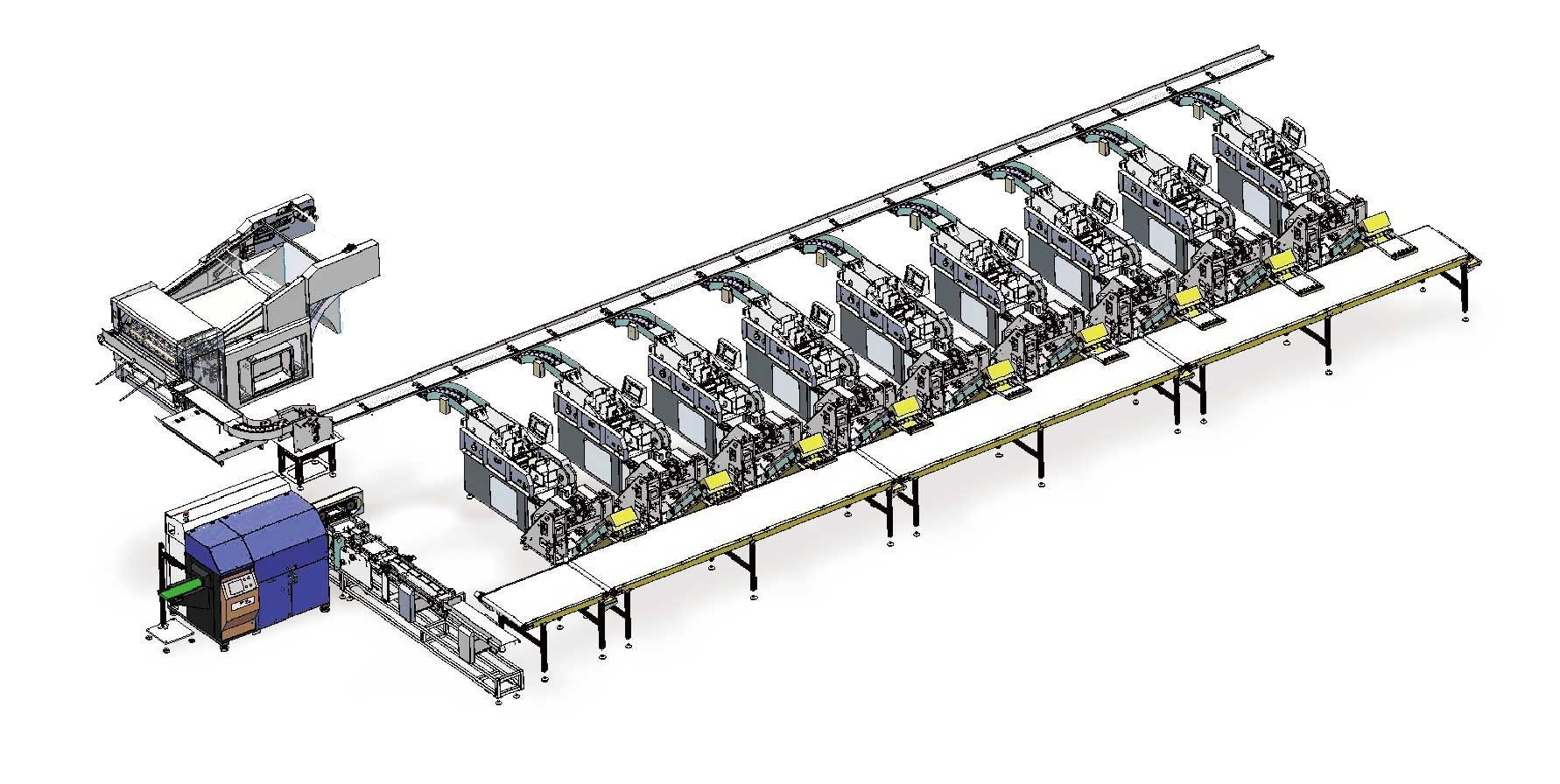

多秤捆紮立體袋全自動生產線

MULTI-SCALE FULLY AUTOMATIC STRAPPING AND 3D PACKING PRODUCTION LINE

- The 3D packaging machine is a product jointly developed with Dutch design experts. Registered Patents for both national and internatonal inventions.

- The speed of 3D packaging is 40% higher than ordinary bags, and the maximum outout is 45 bags / minute, allowing profit to increase more than 30% compared with ordinary bags.

- Includes all the advantages of ordinary bag packaging production lines, wth extremely high accuracy and service life.

- Meets the needs of market packaging requirements for both manufacturers and consumers. Also suitable for packaging leisure foods, with a wider application range.

- The production line can be adjusted of four to twelve scales according to the production capacity.

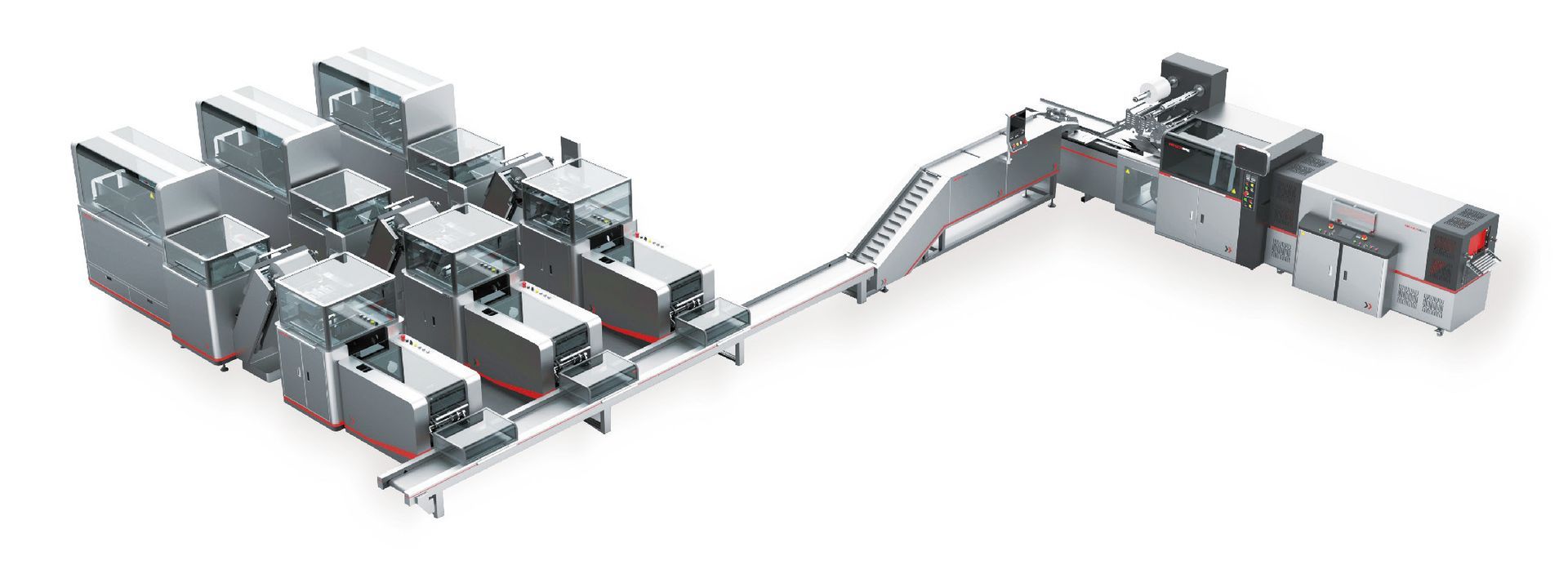

紙包裝智能聯線

FULLY AUTOMATIC PAPER PACKING PRODUCTION LINE

The Smart Packing Line automaticlly loads, weighs, straps, lifts, re-inspects, packs, and delivers. Lowers manpower.

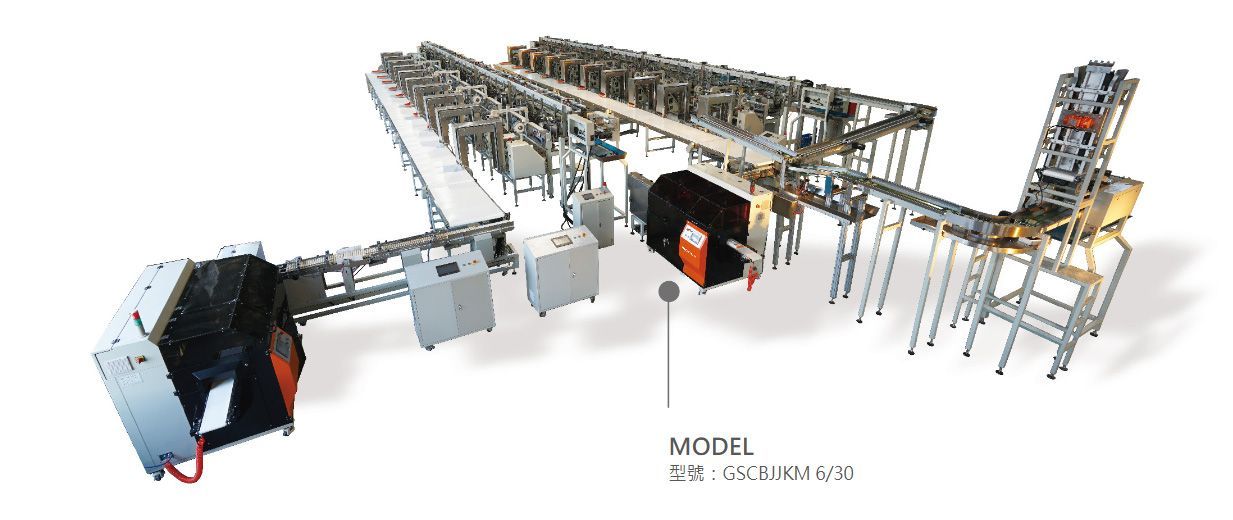

多秤普通塑包捆紮聯線

MULTI-SCALE FULLY AUTOMATIC STRAPPING PRODUCTION LINE

- Centralized control, smart acceleration, and deceleration, and better human-machine interaction.

- Each line only requires 2 to 4 people on duty, and the daily packing is 15 to 40 tons, which is equivalent to about 30 people per day.

- Uses imported electrical components. Frequency conversion speed adjustable. The servo motor controls the sorting grouping and packaging film delivery. Anti-cut and anti empty packaging functions.

- Uses roll film to replace finished packaging bags, saving consumable costs.

- Accurate counting, good compatibility, and suitable for all sizes. Equipped with high-level protective and safe functions.

- The production line can carry out different proportions of the weighing machine from four to twelve scales according to production capacity requirements.

高速秤立體袋包裝聯線

HIGH-SPEED SCALE 3D PACKING PRODUCTION LINE

- This equipment can be used for ordinary packaging and 3D packaging at the same time. Smart control meets international standards of high-end 3D packaging and ordinary plastic packaging.

- Elevated design allows provdes enough space for logiistics to pass freely, saving time, and speeding up efficiency of the workshop.

- Weighing speed is 70% higher than ordinary weighing machines, saving 80% of the floor space. The ergonomic robot arm is designed to be smooth and precise, while still preventing breakage.

- Compatible with smart high-speed weighing and feeding system to complete the material sorting, unloading, and refilling. Automatically adjusts to each weighing machine wth a large conveying capacity.

- Equipped with double-removal automatic weighing and dual-cylinder sorting mode. High accuracy and fast detection speed.

- Adjustable ratios of weighing machines and packaging machines according to capacity requirements.

高速秤捆紮立體袋包裝聯線

HIGH-SPEED AUTOMATIC STRAPPING AND 3D PACKING PRODUCTION LINE

- High-speed weighing machine can be used with common packaging machine and 3D packaging machine. Compatible with international design standards.

- Elevated design allows provdes enough space for logiistics to pass freely, saving time, and speeding up efficiency of the workshop.

- It has the advantages of ordinary multi-scale strapping and packaging, high-speed weighing machine, doubles the efficiency.

- National patent registered with advanced high-end quantitative packaging line.

- Adjustable ratios of weighing machines and packaging machines according to capacity requirements.